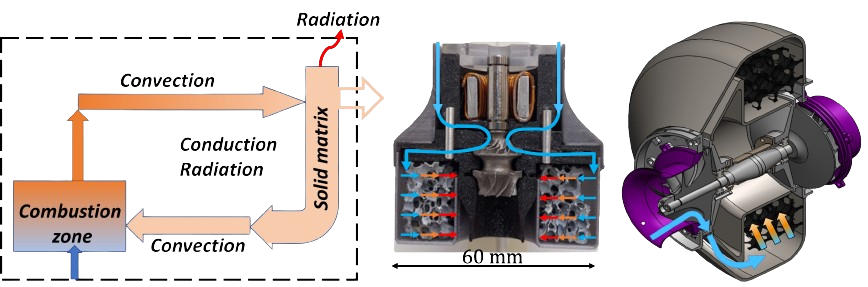

Previous research on ammonia (NH3) combustion has primarily focused on conventional free flames, with limited studies on porous media combustion (PMC). PMC has been successfully demonstrated to achieve low NOx emissions and high combustion efficiency at a fixed combustion location within a multi-layer ceramic foam. However, its applicability in micro gas turbines (MGTs) has been limited due to size constraints and pressure losses. To address these limitations, our work introduced a compact porous inert media (PIM) combustor- tailored for MGTs, as the first study to investigate PMC for gas turbine operation. We successfully demonstrated pure NH3 combustion by achieving dynamic flame stabilization in a radial inward flow configuration. Furthermore, efforts were made to analyze flame stabilization mechanisms in tested PIMs and assessed combustion efficiency by evaluating major pollutant emissions such as NO, N2O, and unburned NH3 and H2 in the exhaust.

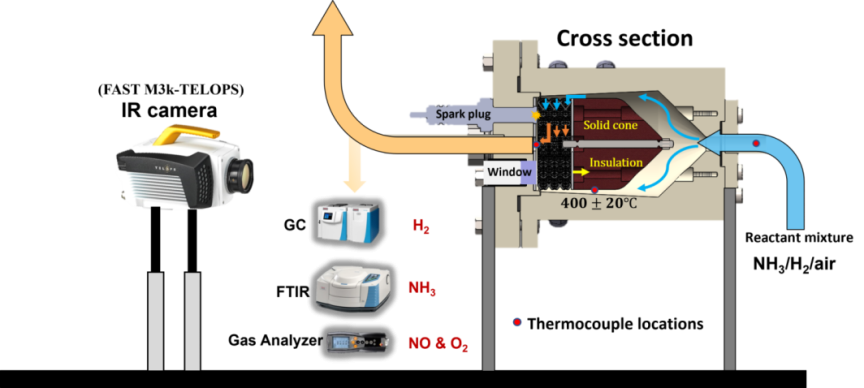

In the radial flow configuration, the cylinder surface area increases with its radius and its velocity distribution is inversely proportional to the radius. As the flow travels through the porous media, it accelerates and is able to find a location at which it tends to stabilize as the kinematic balance between the burning velocity and the fresh mixture velocity is equal. Accordingly, radial PMBs offer a wider range of flame stability and power modulation rates compared to cylindrical axial burners, which are only dynamically balanced in a narrow range of flow rates. A schematic of experimental setup shown below

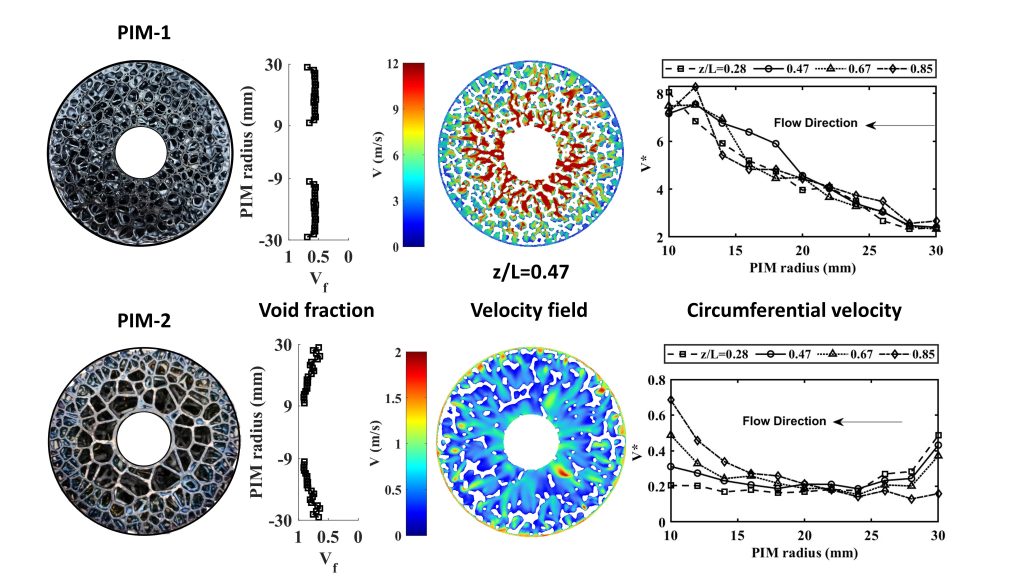

Our study employs a silicon carbide (SiC) ceramic foam with Voronoi lattice structure. We investigated in two distinct porous inert media (PIM) matrices: PIM1, which has a uniform void fraction, and PIM2, which features a linearly graded void fraction from the inner to outer radius. In PIM1, the velocity field steadily accelerates inward due to mass flow continuity. In contrast, PIM2’s graded void fraction results in localized velocity fluctuations, with higher velocities near the outer surface, a drop in the mid-region, and an increase near the inner radius.

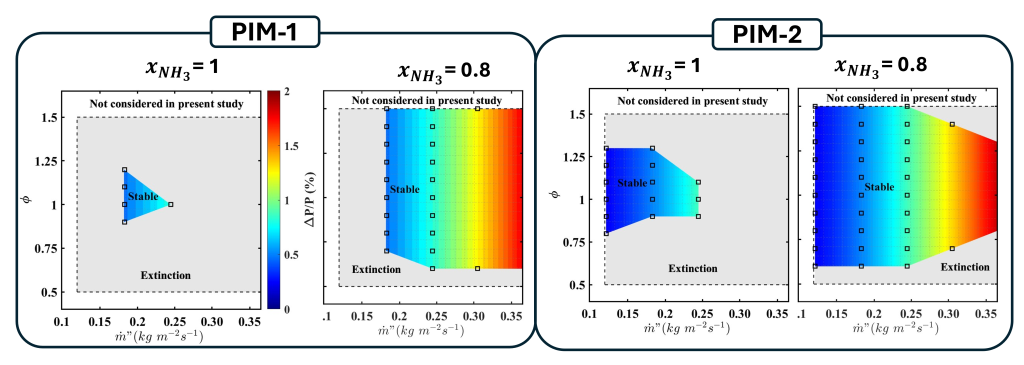

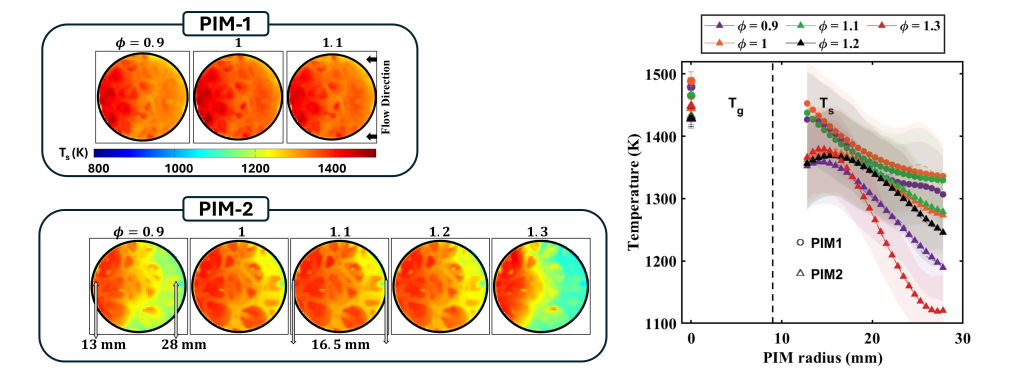

The study evaluated the burner flammability limits for pure NH3 and NH3/H2 mixtures with 20% H2. The results revealed that the stability range for pure NH3 operation in PIM2 extended over a broader range of mass flux compared to PIM1, highlighting the significant impact of the graded porous structure on flame stabilization. A spectrally-filtered infrared imaging technique was employed in a spectral region devoid of gaseous emission from the species present in the combustor, isolating only the surface emissions of SiC to measure the solid-phase temperature, considering the emissivity of the ceramic material.