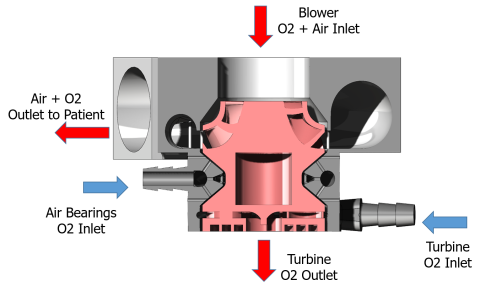

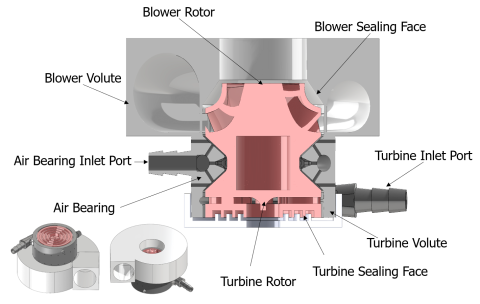

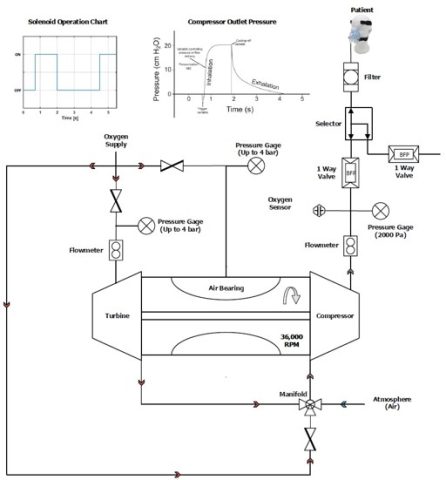

COVID-19 RESPONSE –As part of the ongoing struggle to save the lives of COVID–19 patients, Assoc. Prof. Beni Cukurel and his research group, from the faculty of Aerospace Engineering , are developing a non–motorized respiratory system that connects to the hospital’s oxygen pipeline and does not require an external electrical source. The system adjusts the oxygen concentration to the patient and transfers the air to the required pressure, all through a micro turbine operated by the oxygen stream itself.

Modern ventilator units provide mechanical ventilation by moving breathable air into and out of the lungs – typically expensive machines, with long lead time to manufacture new units.

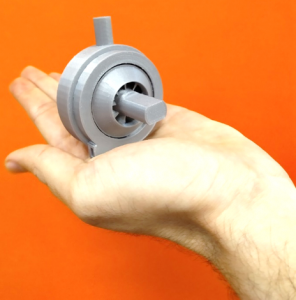

In case of emergency, when existing ventilator units become insufficient, we aim to bridge the gap by additively manufactured blower ventilators, driven by air pressure.

Major benefits include fully additively manufactured, no assembly required, no electrical supply needed, no lubrication. Uses only oxygen supply, which is then rerouted back to patient. All critical components manufactured using common FDM plastic printers within 1 to 3 days.

Implementing additive manufacturing allows to rapidly produce simple and cheap automatic ventilation units. These units can be used in case of emergency to provide critical lung ventilation for patients who would otherwise receive no treatment. Thousands of ventilation units could potentially be manufactured within days using common, cheap, and available FDM printers.