![]() Written and published by N12. Click here for the original article.

Written and published by N12. Click here for the original article.

While the world is striving to improve drone performance by reducing engine sizes, the Technion Institute of Technology in Haifa, Israel cracked down the issue with their innovative approach • A miniscule 3D printed engine will allow flying a drone for a 5-time longer duration at a significantly lower cost.

The world is rapidly changing, especially in light of the COVID-19 era and its seemingly never-ending tiresome procedures. Nowadays, we are constantly presented with various challenges we were previously oblivious to, some of which carry new opportunities. The past year has greatly accelerated the introduction of drones into our lives, in numerous uses, for the transportation of food, lifesaving medicine, including blood transfusion and for the faster and more efficient delivery of consumer goods.

An innovative miniscule engine, developed by the Technion Institute of Technology is designed to increase the flight range of drones by hundreds of percent. The engine, which has already been filed for patent registration, is expected to bring about dramatic changes, which will affect various industries, such as shipping, entertainment, search and rescue services and many more. The engine is not suitable for large aircrafts and is specifically developed for unmanned aircraft weighing 6 kilograms and below.

.

In order to utilize the countless options drones or UAV (unmanned aerial vehicle) can present in our lives, several technological challenges must first be resolved. The most significant of which is flight range – which currently cannot extend far enough before running out of power. Currently, UAVs are powered by electric energy from lithium batteries. This type of energy limits the duration of flight to only tens of minutes, as well as burdening the UAV with its additional weight, thus decreasing drone efficiency and increasing the use cost.

To overcome this challenge, in the last two decades, engineers delved in the ongoing effort to minimize existing configurations of gas turbine engines (fuel-based engines) known as jet engines. However, reducing large engine size affects many features, including the stability of the system, its overall temperature, heat transfer, and gas movement in the combustion chamber. All these features combined significantly reduce the energy efficiency of the engines.

Photo Credit: Nitzan Zohar – Technion PR

The conception that shrinking an existing large engine shall not significantly increase drone reach, along with the main limitation of the UAV domain, led to years of this issue being unsolved. However, this current invention presents a valid solution, which will surely revolutionize the aviation sector.

The development comes from the Turbomachinery and Heat Transfer Laboratory, headed by Assoc. Prof. Beni Cukurel from the Aerospace Engineering Faculty at the Technion. The breakthrough published by Cukurel and his team is based on a fundamental change of perception: instead of reducing the size of existing engines, the researchers developed an entirely new type of engine, based on the unique aerodynamics of gas behavior in small spaces. The engine manages to overcome the limitations of the material as well as the constraints of components found in existing engines.

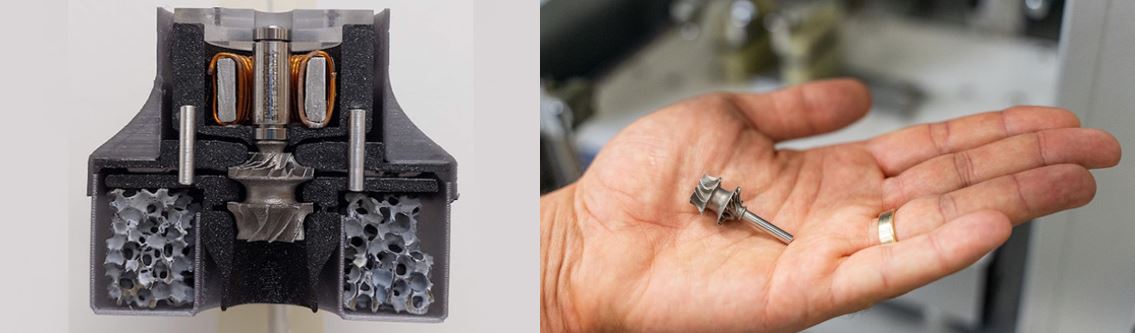

The innovative engine structure of is fundamentally different from common gas turbine engines. For the first time in history, all rotating components in the engine are manufactured at once, as a 3D printed single unit. Moreover, the combustion chamber is also 3D printed and is designed differently than a standard combustion chamber, as its shape resembles a three-dimensional mesh, producing optimal combustion in small chambers.

The result is a miniscule motor, about 5 centimeters in size, which can produce 300 Watts of power. The engine weighs about 200 grams and will be propelled by gas with a total weight of 700 grams, meaning that the entire system will weigh less than 1 kg. The small size and width will generate flight duration of from about 30 minutes up to two and a half hours.

Prof. Chukurel and his team. Photo Credit: Nitzan Zohar – Technion PR

“During the three-year development period, we have improved not only the performance of each engine component, but also the performance of the engine as a whole,” Prof. Cukurel explains to N12. “After completing experiments on each individual component, we estimate that the experiment in the assembled system will be successful as well, advancing us towards the possibility of commercial production. Our ambition is to adapt the engine to diesel, which is relatively cheap, available and is considered a very stable type of fuel. The financial opportunities for the private market alone, excluding the defense and security industry, are estimated at 13.6 billion U.S. dollars. This sum may be multiplied when looking at sales of assembled aircrafts.”

We then asked how the new development may improve our lives. “The target market for drones and small UAVs is a growing market. When it comes to photography purposes or for recreational uses, the prices of drones are estimated at higher than a thousand dollars per unit, while the cost of the battery ranges from 100 U.S. dollars and can climb up to 500 U.S. dollars”, Prof. Cukurel explains. “We estimate that the price of our product will be roughly around 248 U.S. dollars. It is therefore competitive, and much more so when you consider the huge advantage of multiplying flight range as much as times five than the existing average.”

According to the researchers, the potential market value of the product for the year 2023 is around 272 million U.S. dollars in the private market alone. The new technology is essentially a range-increasing technology. It increases the flight time and range by hundreds of percent. The new system is relevant for drones carrying a battery weight of up to 1 kg, with a flight speed of up to 50 km/h – for example drones for light deliveries or drones that carry regular or night vision cameras.

Prof. Cukurel mentions his participating partners in the development: “In the different research phases of the engine development, Lukas Badum and Pavel Kovalyov were involved in the discovery. Lukas deals with the content and optimization of the various engine components as part of his doctoral studies, and Pavel develops the engine’s special combustion chamber as part of MSc degree at the Technion.” This project is including fundamental science research as well as practical engineering. Due to the large potential of the field, new research positions are available in the group.